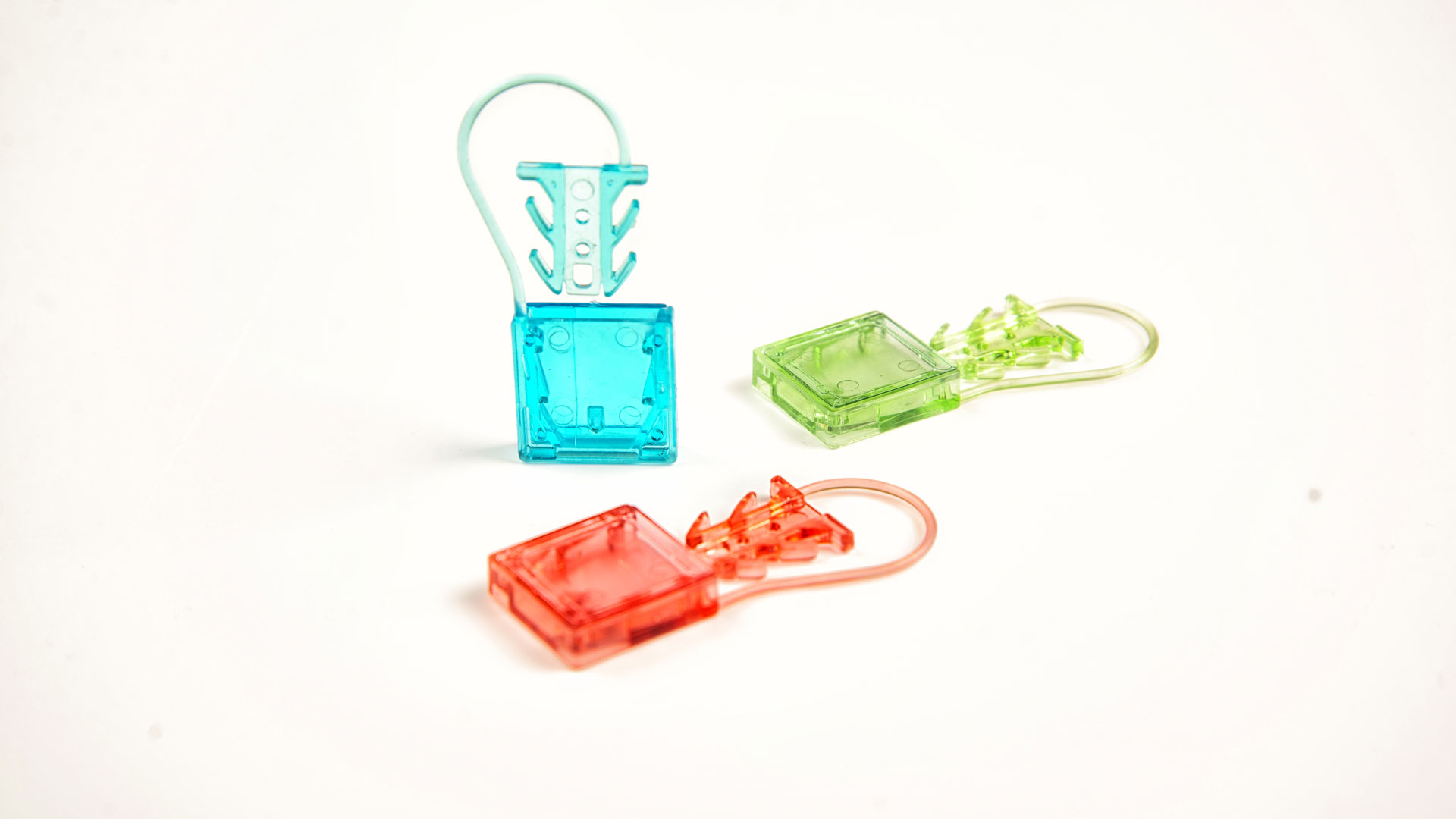

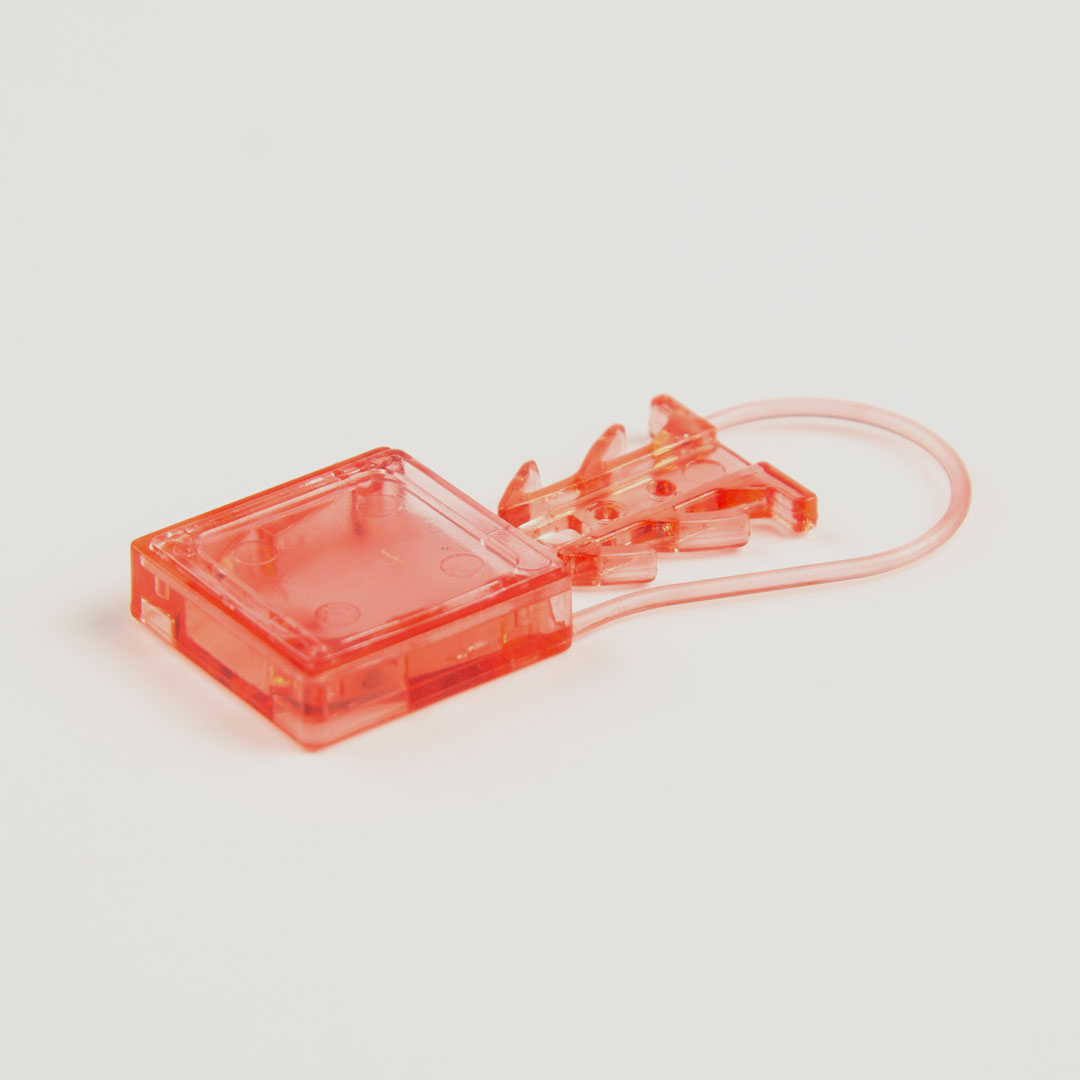

PLS10 PLASTIC SECURITY SEAL

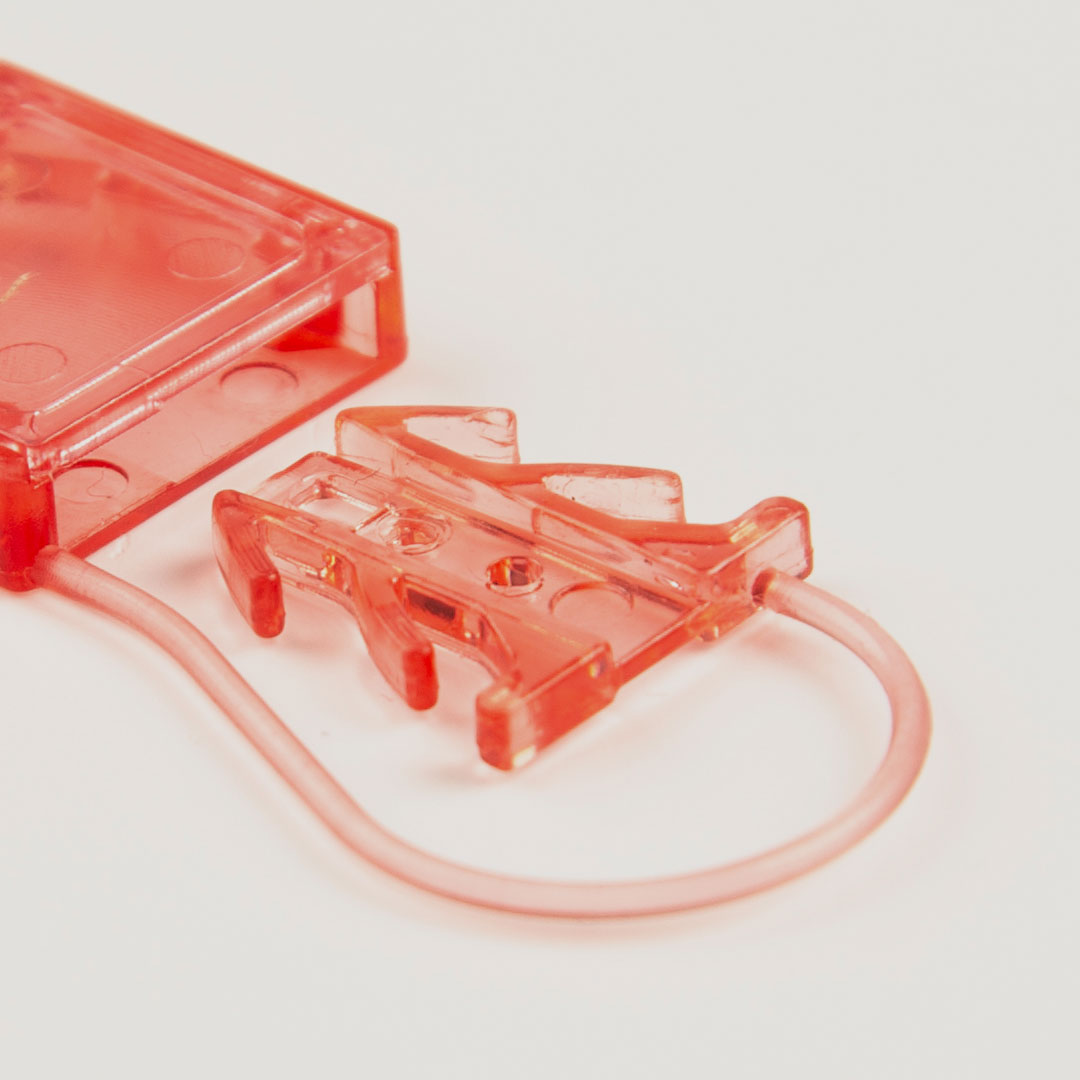

Polycarbonate main body combined with ultrasonic welding consists of an atrium integrated with this body.

All of the plastic parts that make up the body are made of Polycarbonate material. Polycarbonate; It is a top class engineering polymer in terms of heat, impact, rupture and burning, physical and mechanical strength. In addition to preserving its physical and mechanical properties in the range of + 90 ° C / -40 ° C, the component design also provides non-flammability. In addition to preserving its physical / mechanical properties in the range of + 90 ° c / -40 ° c, the component design also provides non-flammability.