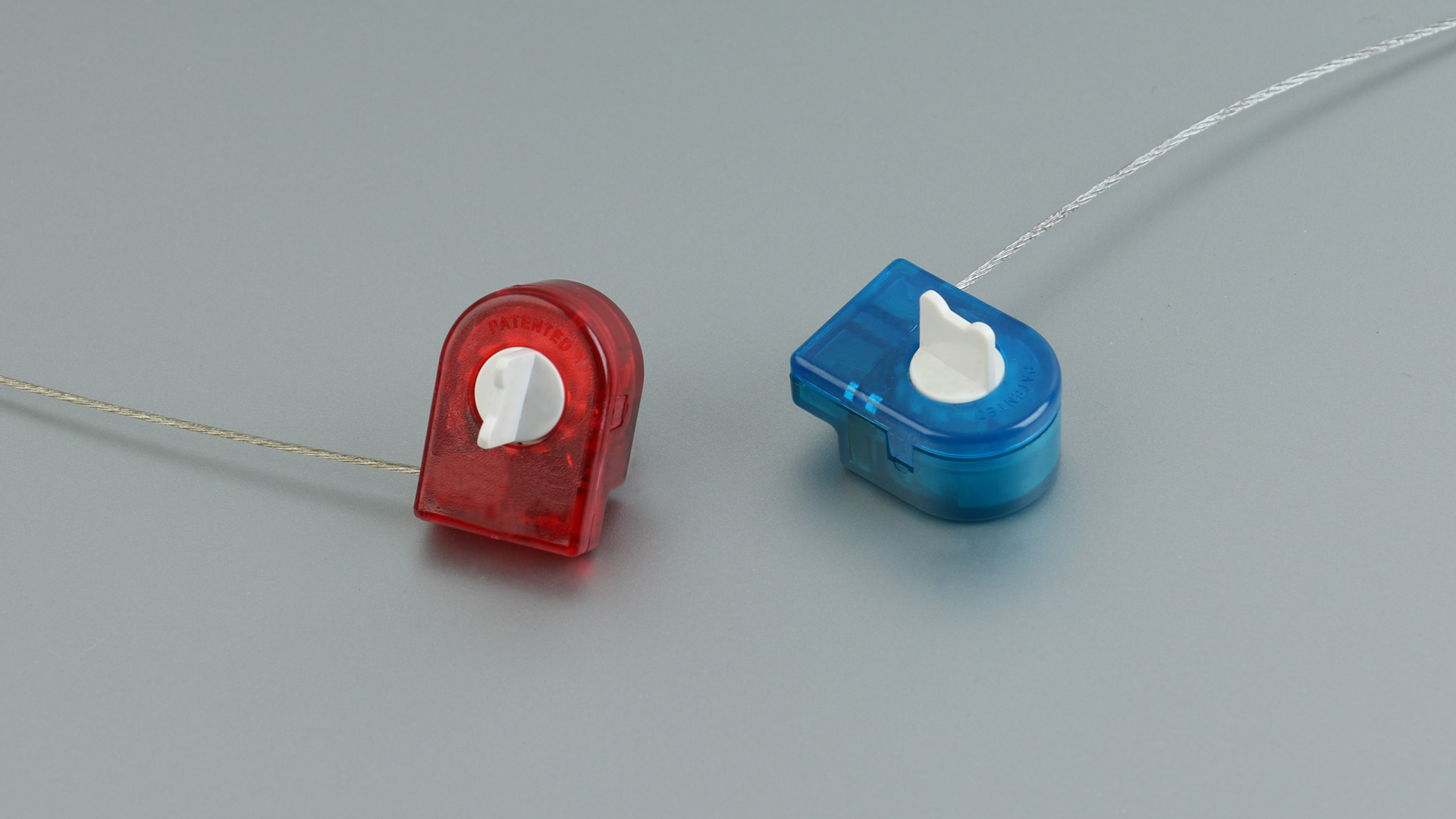

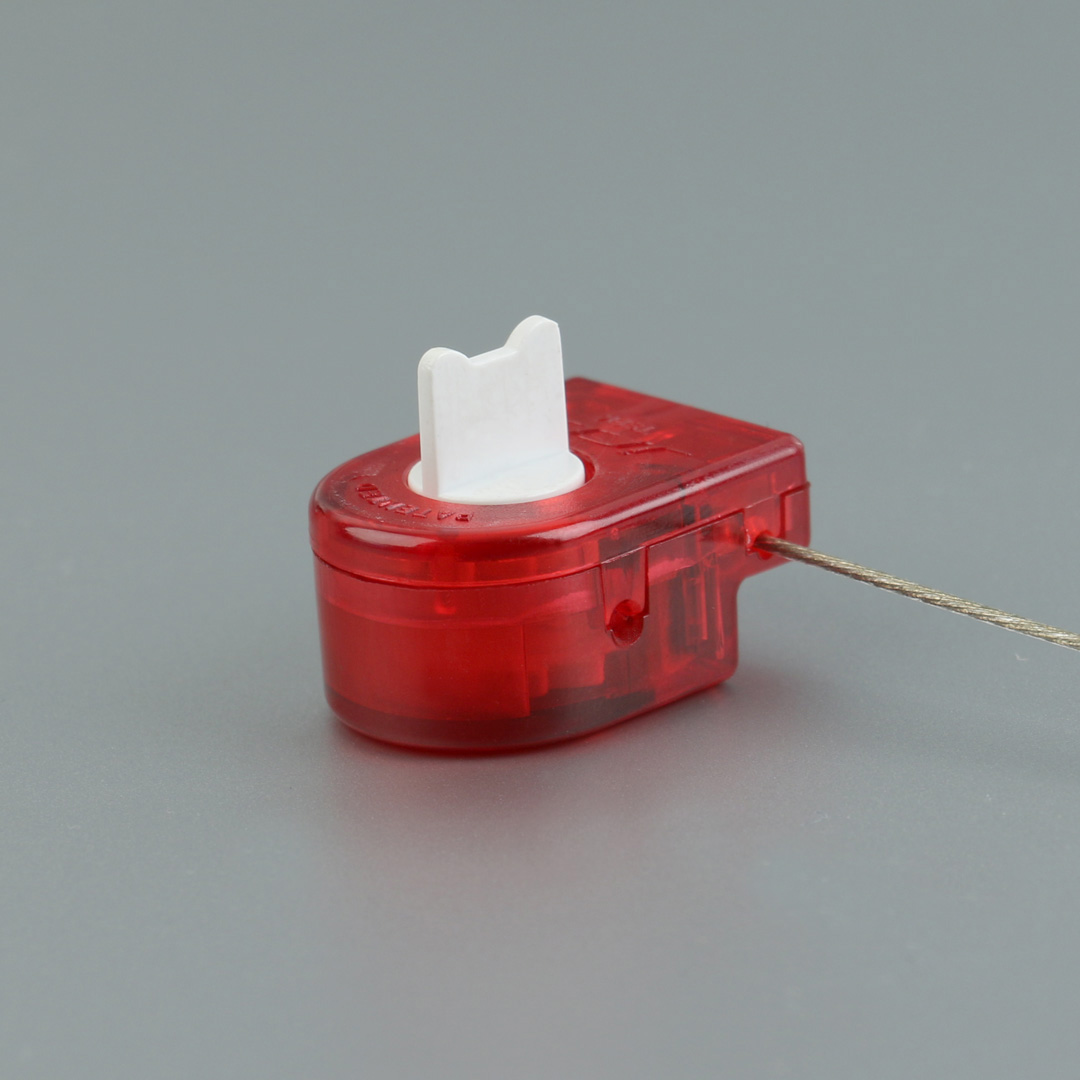

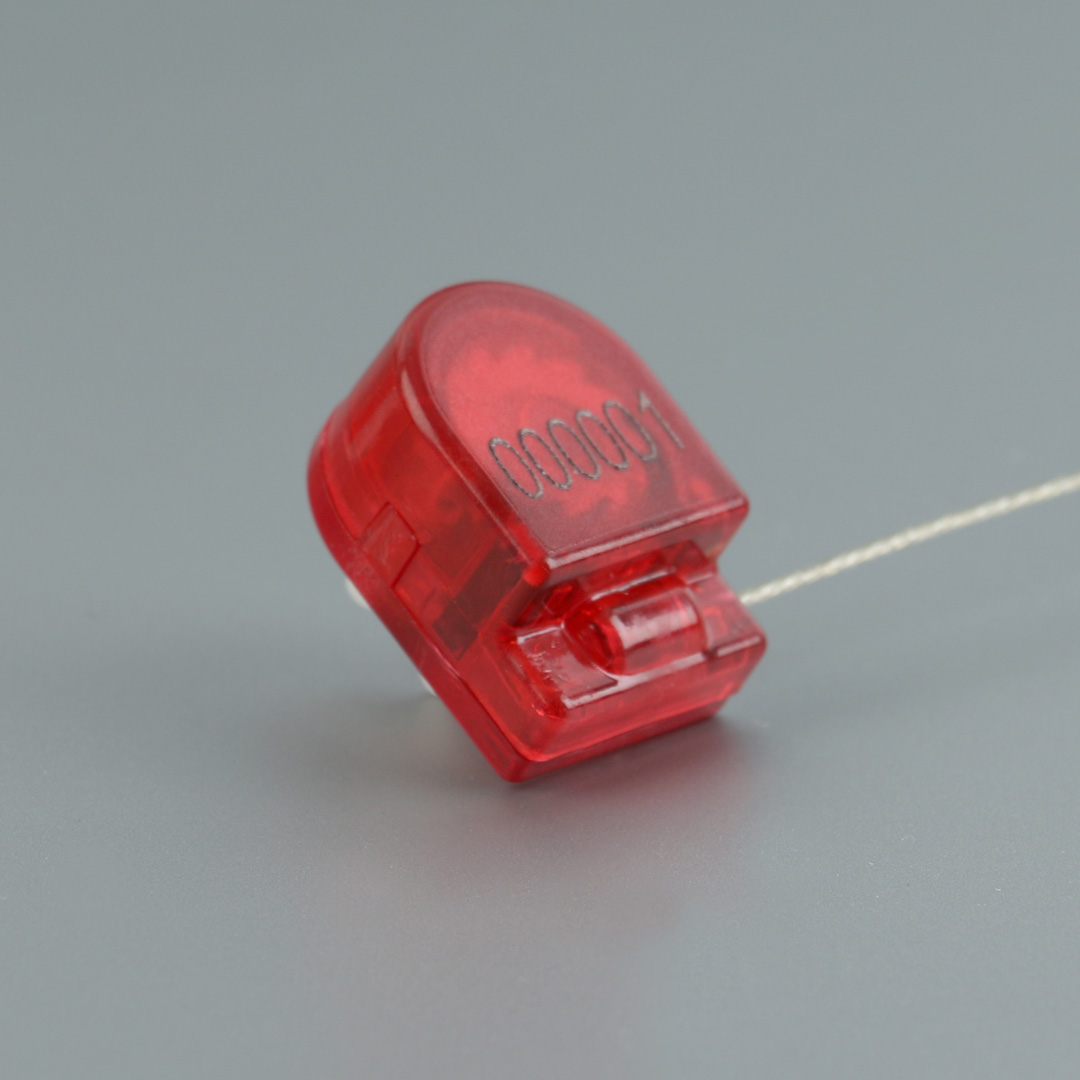

RFID

- RFID chip is a technology that can remotely read and control the quality and quantity information of the sealed material with the hand terminal without the need to contact. The seal is placed inside. It is a highly preferred model with its data hosting characteristics regardless of the information capacity.